Welcome to the Fairsnape blog and webpages.

You will find information and background to myself Martin Brown and Fairsnape here.

“We are on the cusp of something regeneratively wonderful

regenerative or something irreversibly disastrous”

Along with the increased use of the term ‘regenerative’ we have a changing narrative. And this is important, as it is narratives that define us and contribute, in turn, to how we define and shape our future. The future is not something that just happens to us, but it is something that we create. As Arundhati Roy noted in April 2020, we need ‘to imagine the future we want and be prepared to fight for it’. Yet, unless we urgently address the level of ecological and climate literacy, and levels of climate awareness within all areas of education, we will not have the narratives, insights and knowledge to imagine our future, to recognize goodness and what it looks like and to be able to fight for it.

Martin Brown RESTORD 2030

Over the past four years, the RESTORE Cost Action has created an important and significant Regenerative Body of Knowledge, (rBOK), for the built environment, A collection that includes many thought-leading publications, videos, presentations and more, covering the built environment spectrum from changing mindsets and system thinking, to design, construction, operations and internal environments.

Free downloads are listed at end of this post and watch out for forthcoming of workshops, courses and other dissemination events based on the wide scope of the rBOK Regenerative Body of Knowledge.

KEY rBOK PUBLICATONS

RESTORD a regenerative guide for educators, students and practitioners. Editors Martin Brown and Carlo Battisti

RESTORY. FAD_Restory The main results and insight into the project management strategies for RESTORE. Editors Carlo Battisti and Martin Brown

RESTORE Final Book: Rethinking Sustainability Towards a Regenerative Economy 22 Chapters, 45 Authors, 22 Countries, Free open access ebook Editors: Andreucci, M.B., Marvuglia, A., Baltov, M., Hansen, P.

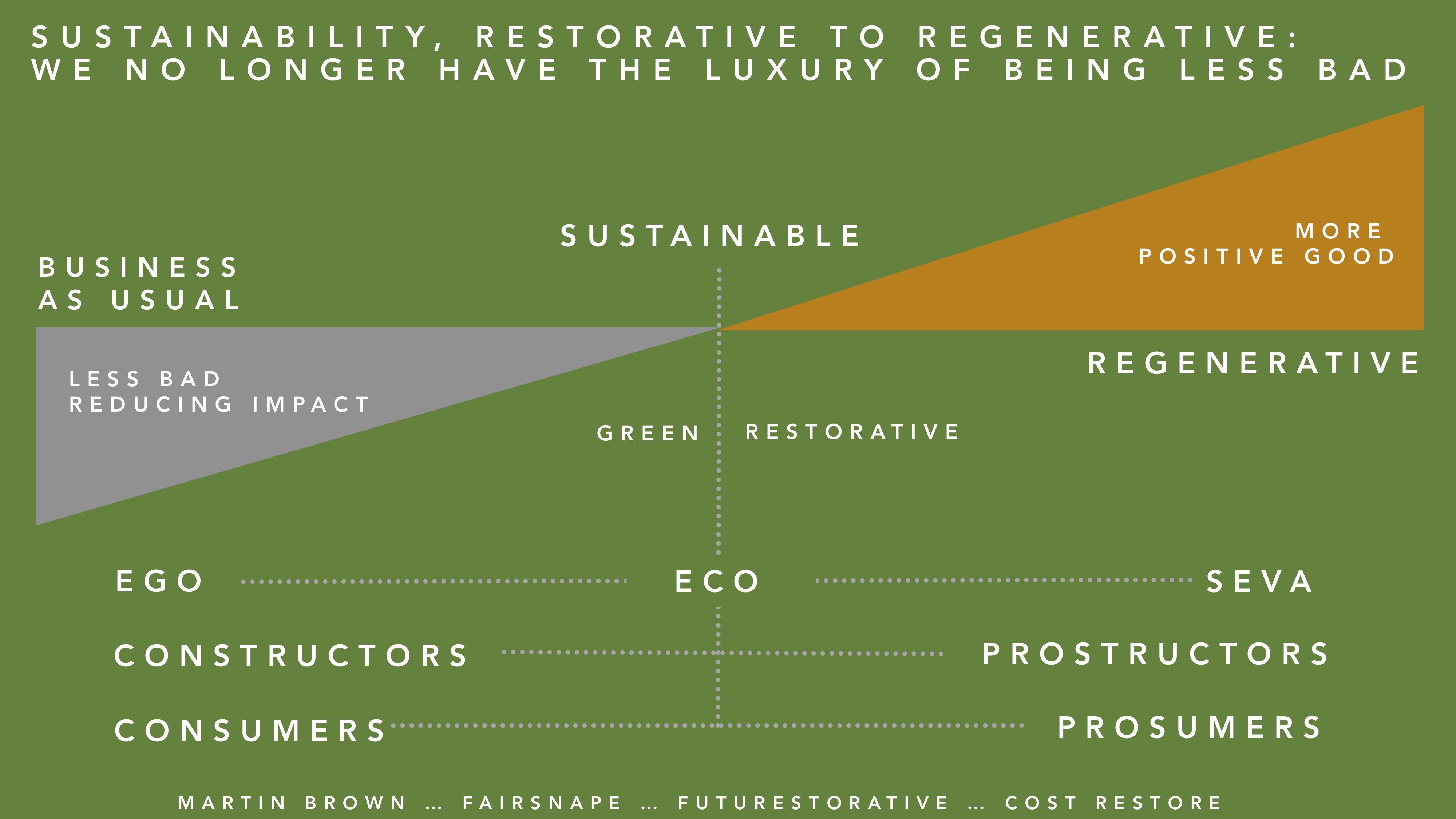

SUSTAINABILITY, RESTORATIVE TO REGENERATIVE An exploration in progressing a paradigm shift in built environment thinking, from sustainability to restorative sustainability and on to regenerative sustainability. Editors Martin Brown and Edeltraud Haselsteiner

REGENERATIVE DESIGN IN DIGITAL PRACTICE A Handbook for the Built Environment. Editors: Emanuele Naboni and Lisanne Havinga

REGENERATIVE CONSTRUCTION AND OPERATION Bridging the gap between design and construction, following a Life Cycle Approach consisting of practical approaches for procurement, construction, operation and future life. Editors: Giulia Peretti, Carsten K. Druhmann.

REGENERATIVE TECHNOLOGIES FOR THE INDOOR ENVIRONMENT Inspirational guidelines for practitioners. Editors: Roberto Lollini, Wilmer Pasut

SCALE JUMPING Regenerative Systems Thinking within the Built Environment Editors: András Reith, Jelena Brajković.

DOWNLOADS

Other publications, papers and videos are available through the RESTORE webpages

A new Arup publication, (

A new Arup publication, (